Miele PW 6323 Barrier Washing Machine

For product advice call.

0800 0853 573

Images are for illustrative purposes only, actual product shipped may vary from that shown.

Product Categories

see similar products in the following categories

Commercial Washing MachinesShare This Product

Key Details

- SKU: WAS015

- Manufacturers Product Code: PW6323

- Manufacturer: Miele

Product Description

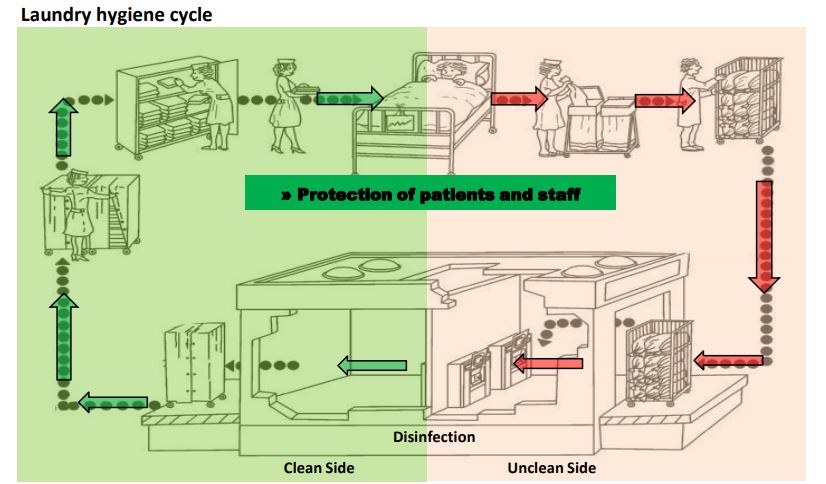

Miele’s new hygienic barrier washing machine extractor is specifically designed to have a separating wall which prevents cross-contamination. This type of washer extractor from Miele is perfect for hospitals and care homes where hygienic conditions are essential.

Giving the user convenience of processing infected and contaminated materials without cross contaminating the clean environment with potentially harmful laundry. Miele has put intelligent features into the design of the Miele PW 6323 barrier washing machine to allow the user to perform the cleaning process as safe as possible.

Features Of The Miele PW 6323 Barrier Washing Machine

The large barrier wall allows the users to add the soiled laundry in one area and remove clean laundry from the other side. By providing the user with the large door on the washer, it makes the machine much easier to load and unload.

Equipped with high-temperature consistency. For reliable cleaning results and maximum hygiene, the temperature of the washing water is monitored constantly.

Miele PW 6323 makes sure that all your laundry gets the best hygienic cleaning during the load cycle. By allowing the user to use both Mieles chemo thermal and thermal programs.

These hygienic cycle programs are specifically designed to kill any infection, by keeping the machine at certain temperatures and for a certain length of time. The electronically controlled dispensing system allows for up to 12 dispenser pumps.

Miele Professional washer-extractors have a large capacity drum to accommodate large loads of laundry. Connection to a hot water supply enables excellent savings in time and energy with minimal effort.

How The Washer Operates.

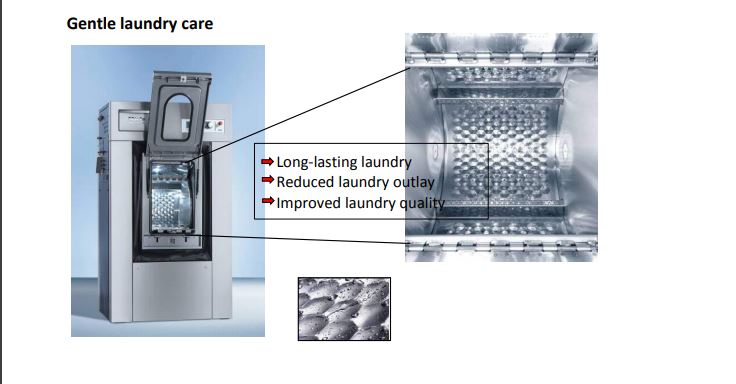

Miele is also glad to have incorporated their patented honeycomb drum feature in the barrier washer. This simple feature will ensure that both the machine and your laundry are protected by a thin film of water.

This film of water allows the laundry to slide around the machine, rather than to rumble around the drum. Providing gentile fabric care while ensuring maximum machine performance.

Miele’s data recording module within the PW 6323 is equipped with profitronic m controls. This programs the machines consumption related data using special software. The scoop and ladel technology within the Miele washing machine, make sure that water enters the machine immediately. Then the laundry sack unravels easily once the cycle has started in the drum.

Only the best quality parts go into the construction of a Miele washing machine. The robust nature of the Miele barrier washer provides smooth operation even at max capacity. One of the most notable features of the Miele PW 6323 is how quiet the machine operates.

When the machine has completed its cycle, the doors on the clean side release, and the drum locks in to place to allow the user to remove the laundry with ease.

Construction Type & Version Construction Type Hygiene Washing Machine

- Range Professional

-

Front Octoblue

- Load ratio 1:10

-

Load in kg 32.0

- Drum volume in l 320

- Door opening [W] in mm clean side 352

- Door opening [H] in mm clean side 593

- Door opening [W] in mm unclean side 352

- Door opening [H] in mm unclean side 593

- Door opening angle in degrees 153

Maintenance-free motor with frequency converter

Patented honeycomb drum

Application Suitable for retirement and care homes

Suitable for facility management

Suitable for commercial laundries

Suitable for fire brigades and rescue services

Suitable for hospitals

Performance data

- Specific water consumption for hot and cold water connection in l/kg 10.31

- Specific energy consumption for hot and cold water connection in kWh/kg 0.13

-

Programme duration in minutes with cold water and hot water connection 61

- Residual moisture with cold rinse in % 47

-

Residual moisture with hot rinse in % 41

- Spin speed in rpm 975

- g factor 360

- Tested operating hours 30,000

Controls Control system Profitronic M Programmability

- Freely programmable

- Max. delay start in h

- Freely selectable

-

Time left display

-

Programme sequence indicator

-

Selectable display languages

- Dispensing

- Detergent drawer

- 4 compartments

-

Liquid dispensing module (optional)

-

Maximum number of connections for liquid dispenser pumps [number] 12 Empty sensor

- Standard electrical connection

- Heating type

- Electrical Electrical connection

- 3N AC 380-415V 50-60HZ

- Heater rating in kW 30.00

- Total connected load in kW 31.00

-

Fuse rating in A 63

- Water connection/drainage Cold water [number]

- 2x 1/2” w/ 3/4” threaded union

- Hot water [number]

- 1x 1/2” hose w/ 3/4” th. union

- Hard water [number]

- 2x 1/2” w/ 3/4” threaded union

- Dump valve

- DN 70

Dimensions and weight

- External dimensions, height in mm 1,718

- External dimensions, width in mm 1,605

- External dimensions, depth in mm 1,070

-

Net weight in kg 860

- Maximum floor loading in N 10741

missions data

- Emissions – sound pressure at workplace 71 dB(A) re 20 µPa

- Heat dissipation into the room in MJ/h 11.20

Features

- Patented pre-spin

-

Cloth reprocessing

- Imbalance monitoring

-

Temperature monitoring

-

Automatic drum positioning and locking

-

Special heater element

-

Automatic load control+

-

Volumetric flow meter (optional)

-

Communication slot

- Emergency switch-off

- Machine-independent accessories

- Efficiency and sustainability

- Recycling rate in % 95

- Connection options

-

Optical interface for service access

-

Serial interface module RS 232 (optional)

-

Peak load cut-out/energy management (optional)

- Operating data acquisition

- Water recovery (optional)

Capacities Synthetic duvets [number] 4 Synthetic pillows [number] 8 Down duvets [number] 4 Down pillows [number] 8 Cotton mops, 40 cm / 190 g [number] 168 Cotton mops, 50 cm / 220 g [number] 145 Microfibre mops, 40 cm / 120 g [number] 267 Microfibre mops, 50 cm / 170 g [number] 188 Test certificate CE

VDE-EMC

- Splash-proof safety rating IPX4

- WEEE

- Complies with Machinery Directive 2006/42/EC